Manufacturing plans for key clean energy technologies are expanding rapidly as investment momentum builds

News

Since late 2022, the estimated output by 2030 from existing and announced manufacturing projects is up by 60% for solar PV and 25% for batteries, driven by supportive policies, corporate strategies and growing demand

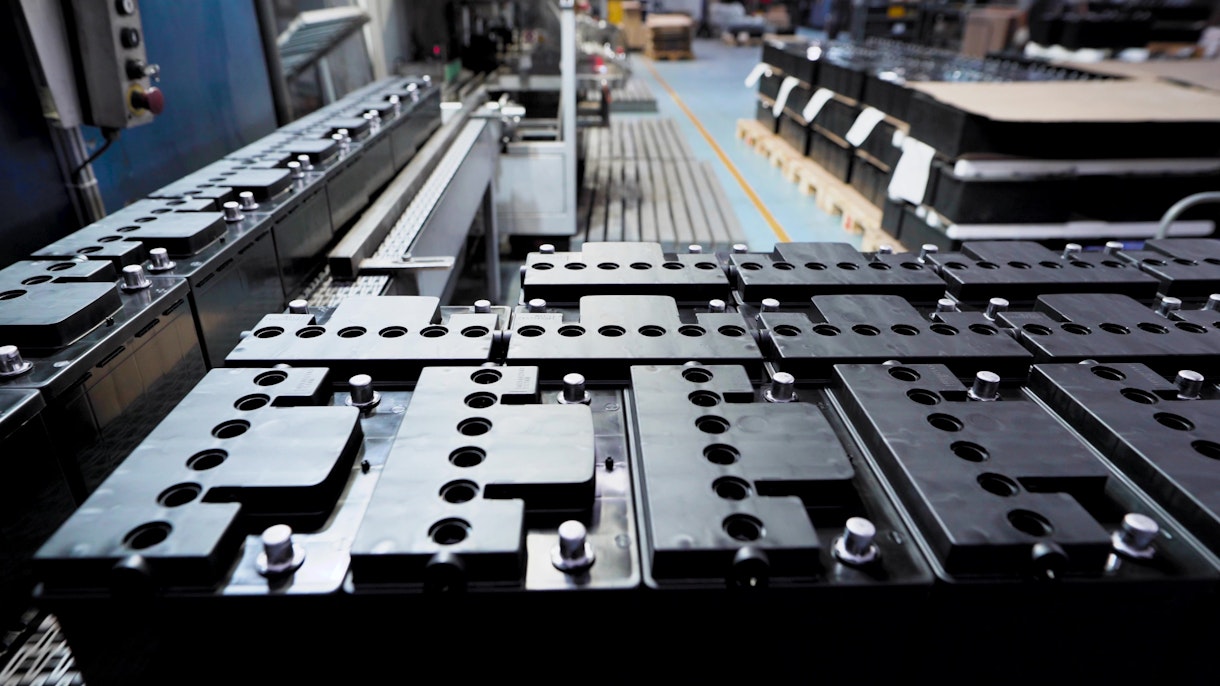

Announcements of new manufacturing projects for several essential technologies for the clean energy transition – including solar PV, batteries and electrolysers – have accelerated in recent months, highlighting the growing global momentum behind the new energy economy, according to IEA analysis published today.

Since late 2022, the estimated output by 2030 from existing and announced manufacturing capacity for solar PV has increased by 60%, for batteries by 25%, and for electrolysers by 20%, propelled by policy support and growing interest from investors, says the new special briefing from the IEA’s Energy Technology Perspectives series.

The report, The State of Clean Technology Manufacturing, examines announced manufacturing projects for solar PV, wind power, batteries, heat pumps and electrolysers to gauge how these plans could shape the clean energy landscape by the end of the decade. The new analysis is intended to inform deliberations at the G7 Leaders Summit in Hiroshima, Japan, this weekend.

If all the projects announced to date were built, the anticipated output of manufacturing capacity for the five clean technologies would reach USD 790 billion a year by 2030. In that situation, global manufacturing capacity for solar PV would comfortably exceed the level needed in the IEA’s Net Zero Emissions by 2050 Scenario for that technology. Battery manufacturing capacity would also meet the level the scenario envisaged for 2030.

However, announcements for wind, heat pumps and electrolysers remain some way off the levels implied by the Net Zero Scenario. And it is important to note that for all five technologies, announced projects may not all go ahead, with most of them yet to receive final investment decisions. But relatively short lead-times for new manufacturing projects – from announcement to construction – mean that there is still scope for the project pipelines for 2030 to evolve significantly in the coming years.

To date, manufacturing capacity in clean energy technologies is highly geographically concentrated. The top three markets account for between 80% to 90% of global manufacturing capacity, depending on the technology. If all announced projects worldwide are completed, the share of manufacturing clustered in these markets would shift to between 70% and 95% by 2030 for different technologies.

“If we look at the projects that are currently under construction or planned worldwide, China is set to strengthen its leading position in key clean energy technologies,” said IEA Executive Director Fatih Birol. “There is a need for effective international cooperation and further diversification to ensure secure and resilient technology supply chains, meet the world’s climate goals and enable all countries to enjoy the economic benefits of the new global energy economy.”

The increased efforts to diversify manufacturing thus far have been supported by major policy announcements in many countries over the last year that are beginning to expand supply chains in different regions. For example, following the adoption of the US Inflation Reduction Act last year, battery manufacturing announcements in late 2022 and early 2023 alone account for nearly half of the sector’s total project pipeline in the United States.

Other recent examples of flagship policies to boost domestic industrial production include the Net Zero Industry Act in the European Union and key milestones in Japan’s Green Transformation programme. Together with China’s current Five-Year-Plan (2021-2025) and India’s Production Linked Incentive scheme, these policies are transforming industrial policy geared toward clean energy technology.

G7 governments have already recognised the importance of building resilient, secure and sustainable supply chains to accelerate the clean energy transition and reduce vulnerabilities associated with undue dependencies. There is much countries can do domestically to proactively address the risks posed to supply chains – including developing industrial strategies that leverage their competitive advantages. But international co-operation will be crucial to ease, hasten and extend any progress that is to be made. With this in mind, the new IEA report concludes with six recommendations for G7 leaders that are also applicable for other interested governments.

The recommendations are focused on actions that require international cooperation, such as coordinating efforts across supply chains, and identifying and building strategic partnerships both within the G7 and beyond, including through facilitating investment in emerging market and developing economies. Development of a platform to inform the process of identifying strategic partnerships for manufacturing is recommended, as well as sharing best practice and promoting technologies and strategies to enhance resource efficiency, thereby increasing the resilience of the supply chain.

In addition to clean technology manufacturing, the issue of critical mineral security is of strategic importance to many countries and an area where the need for international cooperation is acute. These minerals are an essential component in the clean energy transition and diversification is necessary to mitigate disruptions or bottlenecks in supply chains. To address these issues, the IEA will host the first ever IEA Critical Minerals and Clean Energy Summit on 28 September to focus on measures to promote the secure, sustainable and responsible supply of raw materials that have a central role in clean energy transitions around the world. The Summit will convene ministers from countries in the IEA family and beyond – including both large mineral producers and consumers – as well as business leaders, investors, heads of international organisations and civil society representatives.